This example will show you how you can use RoboDK for 5-axis robot machining using the Mastercam plugin. In this example the goal is to trim the excess material around a car hood using a Fanuc robot with a cutting tool mounted on a spindle.

With the RoboDK plug-in for Mastercam you can quickly set up robot machining projects direclty from Mastercam to RoboDK. This plug-in allows you to program more than 50 different robot manufacturers and 500 robots.

The RoboDK plug-in for Mastercam supports NCI (native preprocessed Mastercam files) and standard APT CLS and G-code files. The plug-in is free if you have purchased a RoboDK license.

To start the project, you should select RoboDK’s 5-axis cutting example in the default library.

This example uses the Fanuc M-710iC/45M robot, a cutting tool mounted on a spindle and a jig to hold the the car hood.

Load the station:

1.SelectFile➔![]() Open

Open

2.Locate the5-axis cutting example从Robodk’s examples section:

C:/ Robodk / Simear /Plugin-Mastercam-5-Axis-Cutting.rdk.

Now that you have loaded the station you can open Mastercam and load the projectC:/RoboDK/Other/Plugin-Mastercam/Examples/Car hood.mcam.

Open your 3D object in Mastercam and launch the cutting simulation. You can see that the software adjusted the orientation of the tool to match the cutting surface.

Follow the next steps to load your part into RoboDK:

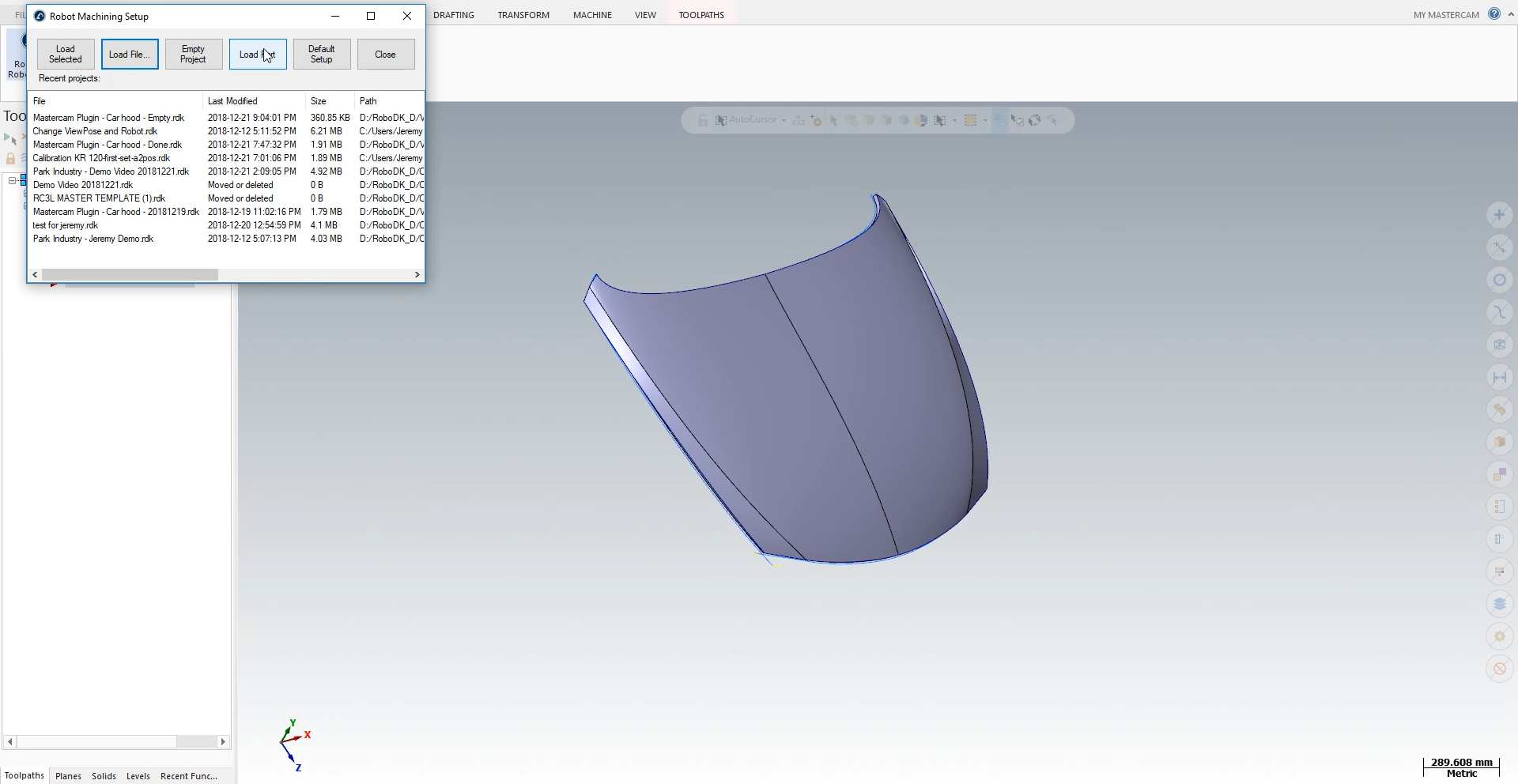

1.选择Robodktab and selectRobodk– Robot setup.

2.SelectLoad Part.

You should see the部分loaded on the active reference frame (Machining Reference) on the jig of the RoboDK station.

The next step is to import the cutting path from Mastercam to RoboDK.

1.选择Robodktab in Mastercam.

2.SelectRobodk– Update selected operations.

3.Go to RoboDK.

Once the robot cutting path has been imported in RoboDK you should see the cutting toolpath attached to the mold reference of your RoboDK station.In the![]() Car hood Settings, make sure that you select the correct robot, reference frame and tool.

Car hood Settings, make sure that you select the correct robot, reference frame and tool.

You can also adjust the value of the approach and retract movements before and after the cutting path. A 400 mm approach/retract should be safe this example. Those movements are now 4 times longer than the default approach/retract and will help avoiding any collision with the part.

You can also adjust the orientation of the part in the lower section of the menu.

下一步是验证是否通过选择将执行路径部分的顺序是正确的![]() Car hood Settings➔更新➔模拟. In this example it is not necessary to readjust the order.

Car hood Settings➔更新➔模拟. In this example it is not necessary to readjust the order.

To generate your robot program, make sure to use the right post processor. Double click on the![]() Fanu M-710iC/45Mrobot and click onSelect Post Processor➔Fanuc R30iA.

Fanu M-710iC/45Mrobot and click onSelect Post Processor➔Fanuc R30iA.

Finally, right click on![]() Car hood➔生成机器人program or pressF6.

Car hood➔生成机器人program or pressF6.

The Fanuc LS and/or TP files are now ready to be transferred to your robot controller.